Complicate and expensive solutions?

Astonomical price for service and spare parts?

-

Nein, Danke.

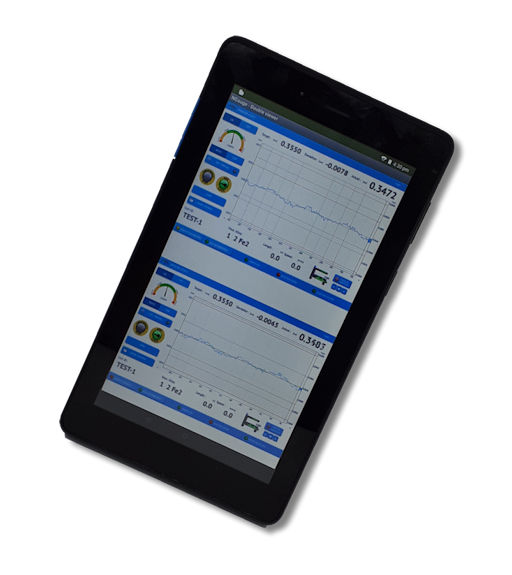

Remote Monitoring using a Tablet and Laptop

| In today’s digitally connected world, remote monitoring of industrial and commercial machinery has become increasingly critical for maintaining productivity, reducing downtime, and improving operational efficiency. Leveraging mobile and portable devices such as tablets and laptops enables technicians, engineers, and management to monitor machine performance in real-time, regardless of their location. This article explores the key components, benefits, and considerations involved in remote machine monitoring using tablets and laptops. |  |

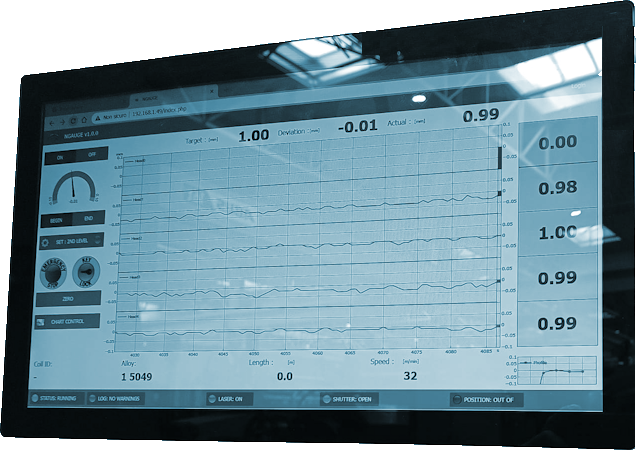

Remote machine monitoring involves collecting and analyzing operational data from a machine or system without being physically present. Sensors installed on the machine collect data, which is then transmitted through a network to an interface that can be accessed on a remote device such as a laptop or tablet.

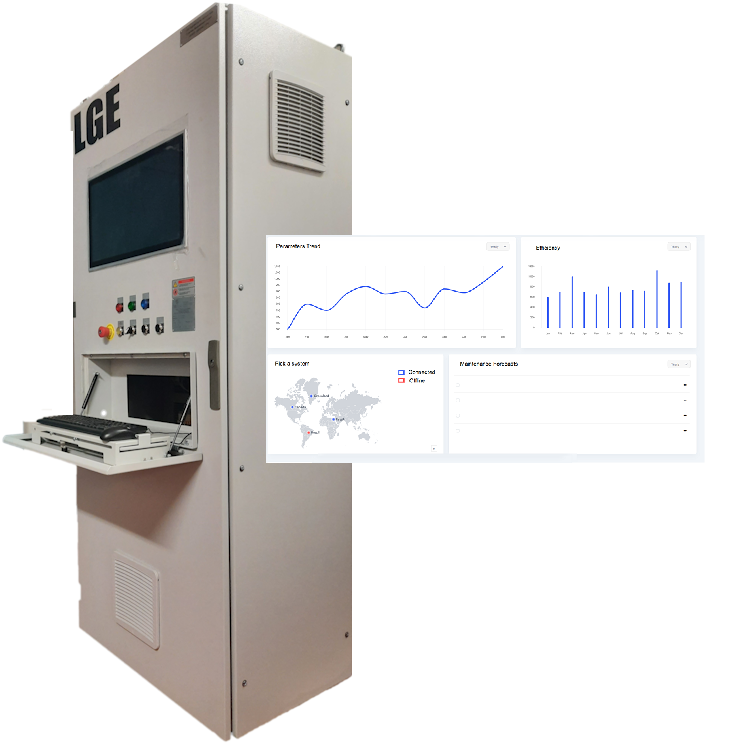

Remote Shark 2.0

A powerful ally to sleep at night.

|

It's Saturday night, and something's wrong with your control systems. The phone rings.It's probably something really small, but no one on site has the right knowledge and is able to intervene. So it's your turn. You could have avoided it! Remote Shark is the definitive software for predictive maintenance and remote management. It's available for all our control solutions and it is your greatest ally in ensuring your systems' continued efficiency. You'll be alerted to any abnormal behavior weeks in advance, giving you plenty of time to address it, ensuring perfect operational continuity. You can have it yourself, or you can subscribe to our predictive maintenance program; we can use it for you and remotely alert you if something is wrong well in advance. |

|

Remote Shark is the ultimate solution for remote monitoring, preventive diagnostics, and predictive maintenance. Each of our control systems monitors its efficiency parameters in real time. These parameters are visible and controllable in the standard packages, but increasingly, managers have very limited time to monitor them due to other responsibilities.

Join our newsletter |

Discover the new cofocal LGaugE

Variations in thickness can compromise structural integrity, lead to product failures, or cause compatibility issues during assembly. Therefore, thickness measurement at multiple points on flat metals is a key quality control process.

Crown, Wedge and Featheredge on flat rolled materials

In the metalworking industry, especially in flat rolling of metals like steel and aluminum, achieving consistent thickness and flatness across the width of the rolled product is crucial. Variations in these parameters can lead to defects, poor product performance, and downstream processing issues. Three key types of thickness profile variations are crown, wedge, and featheredge. Understanding and controlling these variations is fundamental to producing high-quality flat-rolled materials.

Crown refers to the difference in thickness between the center and the edges of a rolled strip. A positive crown means the center is thicker than the edges, while a negative crown means the edges are thicker than the center.

AI transforming Automation and Efficiency

Industrial process control is at the core of manufacturing and production operations, ensuring consistency, quality, and efficiency in systems ranging from chemical plants to automotive assembly lines. Traditionally reliant on programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, and human oversight, industrial control has entered a transformative era driven by Artificial Intelligence (AI).

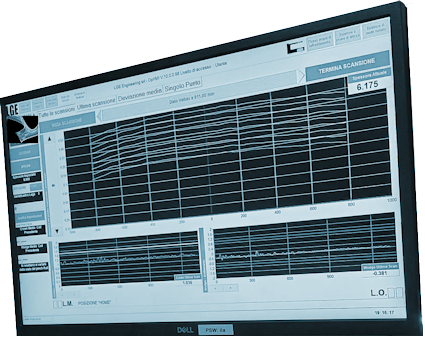

3HS / 5HS Multiple points cross profile thickness measurements

Multiple Points with fixed heads: the 3Hs and 5HS scanners are revolutionizing the way of controlling the thickness on flat laminates in medium critical environments

In industries like automotive, aerospace, and construction, ensuring the consistent thickness of flat metal sheets is crucial. Variations in thickness can compromise structural integrity, lead to product failures, or cause compatibility issues during assembly. Therefore, thickness measurement at multiple points on flat metals is a key quality control process.

3DShaper : shape and dimensions on pipes and hollow profiles

In modern pipes and profiles manufacturing and fabrication, ensuring the conformity of the shape, the quality and integrity is essential for safety, performance, and compliance. Traditional inspection techniques—while useful—can be time-consuming, subjective, or limited in resolution.The alternative is a high-precision, non-contact measurement tool revolutionizing quality controls across industries.

Online shape and measurement for coupling gears

In modern manufacturing and quality control processes, the surface finish of mechanical parts plays a critical role in product performance, durability, and functionality. Whether in the aerospace, automotive, medical, or tooling industries, precise surface texture measurements are essential. One of the most reliable instruments for this purpose is the profilometer.