nGauge Serie

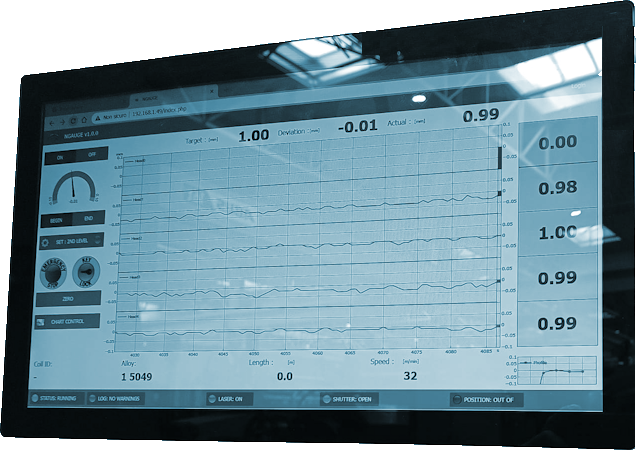

The full digital gauging way: A modern, reliable and extremely high performance non-contact thickness measurement system for flat, hot and cold metallic products, ideal as an input for Automatic Gauge Control systems.

The nGauge system is the result of over 50 years of experience in the field of non-contact measurements on metals. Its predecessors are all our PC-based models that have followed one another over the years, starting from 1985, the year in which our group - first - adopted an industrial PC for the management of the IOs of the industrial measurement systems of the thickness. The nGauge system has a totally digital architecture, both in terms of sensors, signal processing and data transfer protocols.

|

|

nGauge is an easy to setup system. The interconnections are minimal, the sensors are reached by a single cable - with Power on Ethernet power supply - and the output signal arrives at a latest generation PAC (Programmable Automation Controller) type processor which, with its PLC part, controls the IOs, and with its PC part to generate the operator interface, as a web service. Any PC with an internet browser (therefore with any operating system) can be connected via the web and act as an HMI. The operator interface can also be provided as a separate socket or http type server client application. Digital sensors send and receive data over the digital Ethernet iP protocol.Due to its multiple protocols, the nGauge can be easily integrated in new or existing plant automation, to share commands and data on digital or analog.

nGauge is the ideal solution measuring the thickness on metals, on line and no contact: hot and cold production lines, with and without profile scanning of both steel, aluminum, brass, copper, special alloys or other metals.

-

-

- Steel

Measurable thickness range

target from 0.010 mm to 50 mm (hot) - Aluminum

Measurable thickness range

target from 0.007mm to 400mm - Brass / Copper

Measurable thickness range

target from 0.010 mm to 15 mm

- Steel

-

The sensors are extremely reliable and "Mill Duty", designed to work in a continuous cycle H24 and last over time in extreme and critical working conditions.To ensure greater control of the components, the sensors are not externally purchased but are made by us.

- Open protocols and cross-platform web-based software

- Operator interface on separate industrial PC with socket server client application.

- Totally digital sensors of our production on Ethernet Ip protocol

- Generator with water-oil convection cooling therefore absence of criticality in case of lack of cooling up to 2/3 days

- Standard components and redundant safety systems

- Flexibility and modularity of the architecture

- Writing times for AGC with cycles not less than 100 microseconds

- Extremely reduced wiring thanks to the POE power supply of the sensors and peripherals