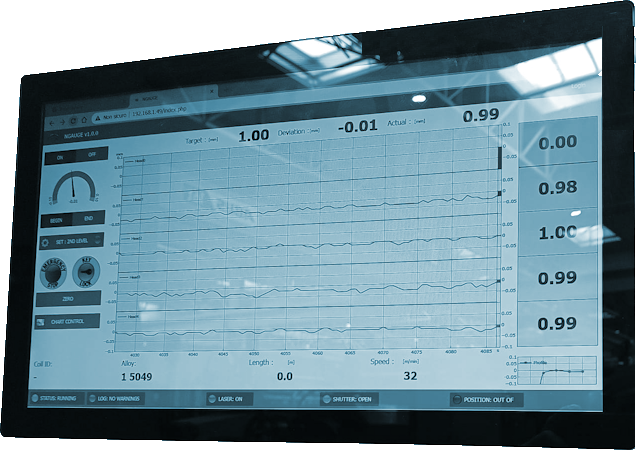

3HS / 5HS Multiple points cross profile thickness measurements

Multiple Points with fixed heads: the 3Hs and 5HS scanners are revolutionizing the way of controlling the thickness on flat laminates in medium critical environments

In industries like automotive, aerospace, and construction, ensuring the consistent thickness of flat metal sheets is crucial. Variations in thickness can compromise structural integrity, lead to product failures, or cause compatibility issues during assembly. Therefore, thickness measurement at multiple points on flat metals is a key quality control process.

While a single thickness measurement can provide a snapshot of material conformity, it does not account for local variations that may occur due to manufacturing processes such as:

- Rolling inconsistencies

- Welding or joining processes

- Thermal distortions

- Wear and corrosion

- Stamping or pressing operations

Measuring at multiple points helps ensure:

- Uniformity across the sheet or part

- Identification of defects or thinning areas

- Compliance with design tolerances

- Increased product reliability

Edge-to-Center Profiling

- Best for: High-speed, non-contact measurement in production lines

- Advantages: Very fast, integrates easily into automated systems

- Measurements are taken at set intervals from the edges to the center.

- Useful to detect tapering or thinning caused by rolling or forming.

Random Sampling

- A statistically valid number of points are selected at random.

- Useful for routine quality checks in high-volume production.

Automated Scanning

- A controlled system scans across the surface.

- Ideal for large sheets or automated environments.

- Can generate 2D or 3D thickness maps.

Data Collection and Analysis

Thickness data collected from multiple points should be:

- Logged with precise location coordinates

- Compared against tolerance thresholds

- Used to compute:

- Minimum/maximum thickness

- Standard deviation

- Mean thickness

- Uniformity ratios

Visualization tools such as heat maps or contour plots are useful to identify localized thinning or defects.

Various industry standards dictate how and where to measure metal thickness. Tolerances depend on application requirements.